If you’re looking for high-quality cutting tools that deliver precision and performance, look no further than Morse Cutting Tools. With over 125 years of experience in the industry, Morse Cutting Tools has established itself as a leader in manufacturing cutting tools that meet the needs of professionals across a variety of industries.

Whether you’re working on a DIY project or need industrial-grade tools for your business, choosing the right cutting tool can make all the difference. In this article, we’ll take a closer look at Morse Cutting Tools and help you choose the right tool for your specific project needs.

H2: What Are Morse Cutting Tools?

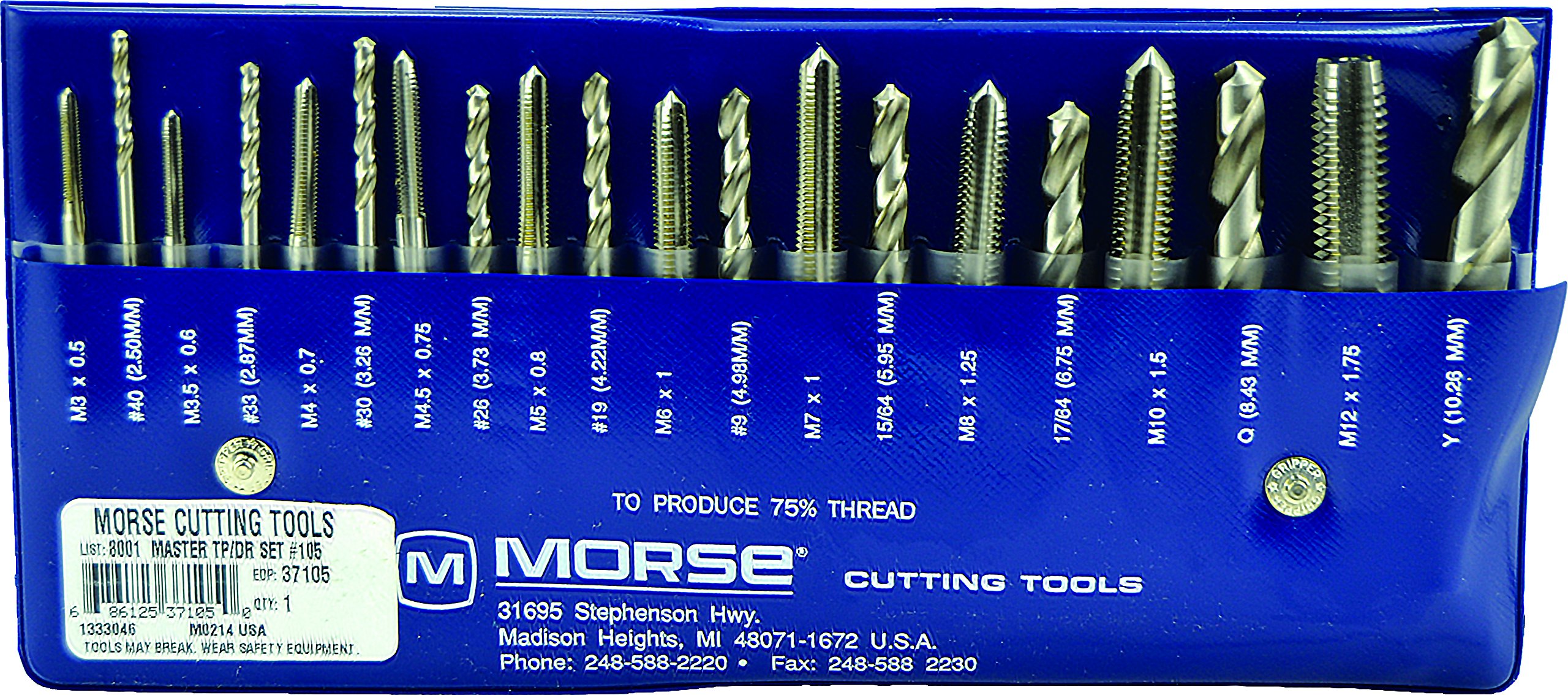

Morse Cutting Tools is a leading manufacturer of cutting tools and accessories made from high-speed steel, carbide, and other materials. Their product line includes drills, taps, end mills, reamers, countersinks, and more. These tools are designed to deliver precision and performance in a variety of applications.

Morse Cutting Tools has been providing quality products to professionals for over a century. They have built an excellent reputation for their commitment to quality and innovation. If you’re looking for reliable cutting tools that will help you get the job done right every time, Morse Cutting Tools is an excellent choice.

H2: Why Choose Morse Cutting Tools?

There are many reasons why professionals choose Morse Cutting Tools over other brands. One of the primary reasons is their commitment to quality. Morse Cutting Tools uses only the best materials to manufacture their products, ensuring durability and reliability.

Another reason why people choose Morse Cutting Tools is their focus on innovation. The company invests heavily in research and development to stay ahead of the curve when it comes to cutting tool technology. As a result, they are continually introducing new products that offer improved performance and efficiency.

Finally, many people choose Morse Cutting Tools because of their exceptional customer service. The company has a dedicated team of experts who are available to answer questions and provide support whenever needed. Whether you need advice on choosing the right tool for your project or help troubleshooting an issue, Morse Cutting Tools is always there to help.

H2: Types of Morse Cutting Tools

Morse Cutting Tools offers a wide range of cutting tools that are suitable for various applications. Let’s take a closer look at some of the most popular types of Morse Cutting Tools:

Drills – Morse Cutting Tools offers a variety of drills, including twist drills, jobber drills, and screw machine drills. These drills are designed to deliver precision and performance in a wide range of materials.

Taps – Morse Cutting Tools taps are made from high-speed steel or carbide and are designed to thread holes in various materials. Their taps come in a variety of styles, including hand taps, spiral point taps, and spiral flute taps.

End Mills – Morse Cutting Tools end mills are used for milling slots, keyways, pockets, and other features in various materials. They offer a range of end mills, including square end mills, ball nose end mills, and corner radius end mills.

Reamers – Morse Cutting Tools reamers are used to enlarge holes with high accuracy. They come in several styles, including chucking reamers, hand reamers, and machine reamers.

Countersinks – Countersinks are used to create tapered holes for screws or bolts. Morse Cutting Tools offers several types of countersinks that can be used on various materials.

H2: How to Choose the Right Morse Cutting Tool

Choosing the right cutting tool can be challenging, especially if you’re not familiar with the different types available. Here are some factors to consider when choosing a Morse Cutting Tool:

Material – The material you’re working with will determine the type of cutting tool you need. For example, if you’re working with metal, you’ll need a carbide or high-speed steel cutting tool.

Application – The application you’re working on will also determine the type of tool you need. For example, if you’re drilling a hole, you’ll need a drill bit. If you’re milling a slot, you’ll need an end mill.

Size – The size of the tool is also essential. You’ll need to choose a tool that is the right size for your project. Choosing the wrong size can result in poor performance and potential damage to your workpiece.

Quality – Finally, it’s essential to choose a high-quality cutting tool from a reputable brand like Morse Cutting Tools. Investing in quality tools will save you time and money in the long run.

H2: Tips for Using Morse Cutting Tools

Here are some tips to help you get the most out of your Morse Cutting Tools:

Use the right speed and feed rates – Using the correct speed and feed rates will ensure that your cutting tools perform optimally.

Keep your tools sharp – Dull tools can cause poor performance and damage to your workpiece. Keep your tools sharp by using sharpening equipment regularly.

Use lubrication – Lubrication can help extend the life of your cutting tools and improve performance.

Take breaks – Taking regular breaks when using cutting tools can prevent fatigue and improve accuracy.

H2: Conclusion

Morse Cutting Tools is an excellent choice for anyone looking for reliable, high-quality cutting tools. With their commitment to quality, innovation, and customer service, they have established themselves as a leader in the industry.

When choosing a Morse Cutting Tool, consider factors such as material, application, size, and quality. By following best practices such as using the correct speed and feed rates and keeping your tools sharp, you can get the most out of your Morse Cutting Tools.

We hope this guide has been helpful in choosing the right Morse Cutting Tool for your specific needs. For more information on Morse Cutting Tools, visit their website or check out the wiki reference below.

Wiki Reference: https://en.wikipedia.org/wiki/Morse_Cutting_Tools