Are you tired of constantly being bogged down by excess inventory? Do you find yourself struggling to keep up with demand while simultaneously trying to avoid overstocking? If so, then it’s time to consider implementing a Just-In-Time (JIT) inventory system.

In this article, we will explore how JIT can be an effective tool for identifying savings and reducing inventory levels. From understanding the basics of JIT to exploring its benefits and challenges, we’ll cover everything you need to know to get started.

What is Just-In-Time Inventory?

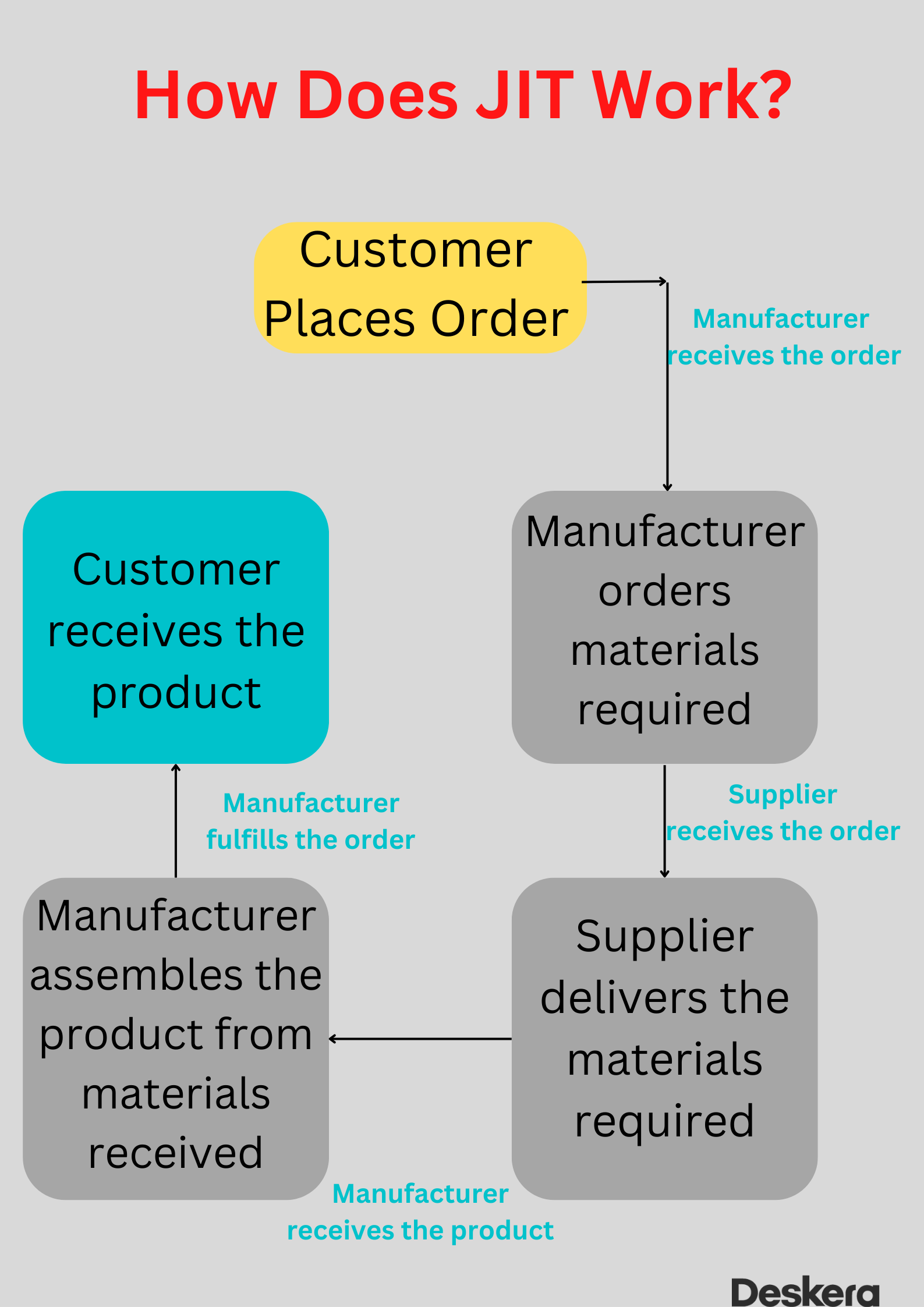

At its core, JIT is a philosophy that emphasizes the importance of having just enough inventory on hand to meet demand. Rather than stocking up on excess inventory in anticipation of future demand, JIT relies on a more proactive approach that seeks to minimize waste and improve efficiency.

By maintaining lean inventories, businesses are able to reduce their carrying costs, such as storage and insurance fees. Additionally, they can free up valuable space within their facilities that can be used for other purposes.

The Benefits of JIT

Implementing a JIT system offers numerous benefits for businesses of all sizes. Here are just a few:

1. Cost Savings – By reducing inventory levels, businesses can save money on carrying costs and reduce the likelihood of obsolete or expired products.

2. Improved Efficiency – With less excess inventory on hand, businesses can streamline their operations and focus on meeting current customer demand instead of trying to anticipate future needs.

3. Increased Responsiveness – By maintaining lean inventories, businesses can quickly respond to changes in customer demand or market trends without being weighed down by excess inventory.

4. Better Quality Control – With fewer products in stock, businesses can more easily monitor product quality and make necessary adjustments before releasing them to customers.

Challenges of JIT

While there are many benefits associated with implementing a JIT system, there are also some challenges that businesses must be prepared to address. Here are a few:

1. Supply Chain Disruptions – JIT relies heavily on timely and reliable deliveries from suppliers. Any disruptions within the supply chain can quickly derail the entire system.

2. Increased Risk – With fewer products on hand, businesses run the risk of stockouts if demand exceeds expectations or if there are delays in delivery.

3. Dependence on Technology – JIT requires sophisticated technology to accurately track inventory levels and anticipate future demand. This technology can be expensive and difficult to implement.

4. Cultural Shift – Implementing a JIT system requires a significant cultural shift within an organization. Employees must be willing to embrace new ways of working and be open to change.

Implementing a JIT System

If you’re interested in implementing a JIT system within your business, here are some steps you can take to get started:

1. Assess Your Current Inventory Levels – Before you can begin implementing a JIT system, you need to understand your current inventory levels and identify areas where improvements can be made.

2. Evaluate Your Suppliers – To successfully implement JIT, it’s important to have reliable suppliers who can deliver products on time and in the quantities needed.

3. Invest in Technology – To accurately track inventory levels and anticipate demand, you’ll need to invest in sophisticated technology such as inventory management software.

4. Train Your Employees – Successfully implementing a JIT system requires buy-in from employees at all levels of your organization. Be sure to provide training and education on the benefits of JIT and how it works.

Conclusion

In conclusion, inventory reduction via JIT is an effective tool for identifying savings and improving efficiency within your business. While there are certainly challenges associated with implementing a JIT system, the benefits far outweigh the risks for most businesses.

By maintaining lean inventories, focusing on meeting current customer demand, and investing in sophisticated technology, businesses can reduce their carrying costs, improve quality control, and increase their responsiveness to changing market conditions.

If you’re interested in implementing a JIT system within your business, be sure to assess your current inventory levels, evaluate your suppliers, invest in technology, and train your employees. With the right approach and mindset, JIT can be a powerful tool for reducing inventory levels and improving overall business performance.

References:

https://en.wikipedia.org/wiki/Just-in-time_(business)

https://www.investopedia.com/terms/j/jit.asp

https://www.scmr.com/article/the_benefits_and_challenges_of_jit