Are you tired of uneven surfaces on your workpieces? Do you want to achieve a smooth and polished finish without spending too much time and effort? Look no further than the deburr hand tool!

In this article, we will discuss everything you need to know about deburr hand tools – from their types, uses, benefits, and more. Whether you are a DIY enthusiast or a professional metalworker, this guide will help you understand how deburring can improve your workflow and product quality.

What is Deburring?

Before we dive into the details of deburr hand tools, let us first define what deburring means. Deburring is the process of removing burrs or sharp edges from a workpiece after it has been machined or cut. Burrs are small protrusions that form on the surface of the material due to the cutting process.

Burrs are not only unsightly but also pose safety hazards as they can cause cuts and injuries. Moreover, burrs can affect the functionality of parts and components as they interfere with their fit and movement.

Deburring is essential in various industries such as automotive, aerospace, medical, and electronics. It ensures that the final product meets the required specifications and standards.

Types of Deburring Tools

There are several ways to deburr a workpiece – by hand using files or sandpaper, by machine using grinders or tumblers, or by chemical processes using acids or solutions. However, in this article, we will focus on manually operated deburr hand tools that are widely used in metalworking.

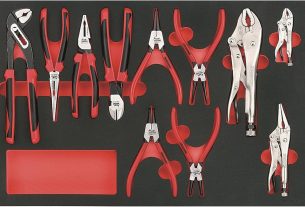

Here are some of the common types of deburr hand tools:

1. Chamfering Tools

Chamfering tools create beveled edges or chamfers on sharp corners and edges. Chamfers not only remove burrs but also improve the aesthetics and functionality of parts by reducing stress concentration and improving the flow of fluids.

Chamfering tools come in various shapes and sizes, including countersinks, deburring cutters, and chamfer mills. They can be operated by hand or using power tools such as drills or lathes.

2. Scrapers

Scrapers are handheld tools that scrape off burrs and rough spots on flat surfaces. They have a blade or edge that is angled to remove material at a consistent depth. Scrapers are commonly used in woodworking and metalworking for finishing and smoothing surfaces.

3. Rotary Tools

Rotary tools are versatile hand-held power tools that use small rotating bits or accessories to grind, sand, cut, or polish materials. They can be used for deburring, engraving, carving, and other precision tasks.

Rotary tools come in different models and brands, including Dremel, Foredom, and Black+Decker. They require attachments such as cutting wheels, grinding stones, sanding drums, or polishing pads to perform specific tasks.

4. Hand Files

Hand files are classic deburr hand tools that have been used for centuries in metalworking. They have a long handle with a tapered blade that has teeth or ridges on one or both sides. Hand files come in various shapes and sizes such as flat files, half-round files, round files, and triangle files.

Hand files can be used to remove burrs on edges and surfaces of different materials such as metals, plastics, wood, and ceramics. They require skill and patience to use effectively but provide excellent results when done correctly.

Benefits of Deburring

Now that we know what deburring is and the types of deburr hand tools available let us discuss the benefits of deburring:

1. Improved Safety

Deburred parts are less likely to cause cuts or injuries to workers handling them. Smooth edges reduce the risk of sharp points snagging clothing or skin.

2. Enhanced Functionality

Deburred parts fit better and move more smoothly, which reduces the wear and tear on machines and equipment. Smooth surfaces also improve the flow of fluids such as oil or gas, increasing their efficiency.

3. Better Aesthetics

Deburring improves the appearance of finished products by removing unsightly burrs and rough spots. This enhances the overall quality and value of the product.

4. Cost Savings

Deburring can reduce production costs by preventing rework or rejection of defective parts. It also prolongs the lifespan of tools and equipment, reducing maintenance and replacement costs.

Tips for Using Deburr Hand Tools

Now that we understand the benefits of deburring let us discuss some tips for using deburr hand tools effectively:

1. Choose the Right Tool for the Job

Different materials and shapes require specific deburr hand tools. Use the appropriate tool for the task to achieve optimal results.

2. Wear Protective Gear

Deburring generates dust, debris, and metal shavings that can be harmful to your eyes, skin, and lungs. Wear safety goggles, gloves, and a mask to protect yourself from these hazards.

3. Use Proper Technique

Follow the guidelines provided by the manufacturer for using deburr hand tools correctly. Avoid excessive pressure or force that can damage the workpiece or tool.

4. Clean Tools After Use

Clean deburr hand tools after use to prevent rusting or contamination that can affect their performance in future tasks.

Conclusion

In conclusion, deburr hand tools are essential for achieving smooth finishes on workpieces in various industries such as automotive, aerospace, medical, and electronics. Chamfering tools, scrapers, rotary tools, and hand files are some of the common types of deburr hand tools available.

Deburring offers many benefits such as improved safety, functionality, aesthetics, and cost savings. Effective use of deburr hand tools requires choosing the right tool for the job, wearing protective gear, using proper technique, and cleaning tools after use.

We hope this guide has provided you with valuable insights into deburr hand tools and their uses. For more information, refer to the references below.

References:

– https://en.wikipedia.org/wiki/Deburring

– https://www.machiningnews.com/2018/08/deburring-tools-and-their-uses/

– https://www.thesprucecrafts.com/best-deburring-tools-for-sharp-edges-4784942

– https://www.mmsonline.com/articles/deburring-tools-how-to-choose-the-right-one

– https://www.engineeringclicks.com/deburring-hand-tools-a-comprehensive-guide/