Are you seeking to improve the efficiency and accuracy of your machining operations? Do you want to minimize the risk of human error and increase productivity? If so, then investing in a tool presetter can be a game-changer for your manufacturing process.

A tool presetter is an essential device that allows machinists to accurately measure and set tools outside of the machine. This means that operators can check their cutting tools’ dimensions and make necessary adjustments before setting them up in the CNC machines. The use of a tool presetter eliminates the need to make manual measurements, saving time, resources, and reducing the risk of errors.

In this article, we’ll explore what a tool presetter is, how it works, its benefits, and why you should consider investing in one for your business.

Understanding Tool Presetters

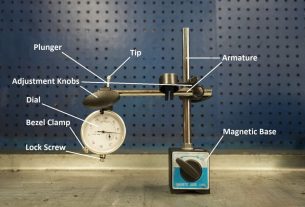

A tool presetter is a measuring instrument that allows machinists to measure the cutting tools’ physical dimensions precisely. The device measures the length, diameter, runout or concentricity of the tool tip, and other critical parameters. It also checks for wear on the tool’s tip and calculates any required offsets needed in programming.

Tool presetters come in various models and sizes with different features. They range from basic bench-top models to automated systems with robotic arms that can handle multiple tools at once.

The machine’s software also plays an important role in its functionality. Advanced software enables machinists to store measurement data digitally, create custom tooling libraries for future use, and track tool usage history.

How does a Tool Presetter Work?

A typical tool presetter consists of several components: a base plate or worktable where tools are placed; an optical camera system or laser sensors that capture precise measurements; and software that collects the data and displays it on a computer monitor.

To use a tool presetter, machinists first place the cutting tool in the device’s holder, which is usually a collet or a chuck. The holder is then mounted onto the machine’s base plate or worktable.

The operator then activates the camera system or laser sensors, which capture images of the tool’s profile and dimensions. The software analyzes this data, calculates any offsets or adjustments needed, and displays it on a computer monitor.

Machinists can then make changes to their CNC program or tool offsets as needed based on the information provided by the tool presetter.

Benefits of Tool Presetters

Investing in a tool presetter offers significant benefits for precision machining operations, including:

1. Improved Accuracy

Using a tool presetter eliminates manual measurement errors and ensures that cutting tools are precisely set up in the CNC machines. This improves accuracy and reduces scrap rates, resulting in higher quality parts.

2. Increased Efficiency

With a tool presetter, machinists can quickly and accurately measure multiple tools before setting them up in the CNC machines. This saves time and increases productivity by reducing downtime due to manual measurements.

3. Reduced Costs

By reducing scrap rates and increasing productivity, investing in a tool presetter can lead to cost savings over time for manufacturing businesses.

4. Customization

Advanced software allows machinists to create custom tooling libraries for future use. This means that they can easily access previous measurements and make necessary adjustments without having to repeat the measurement process.

Why Invest in a Tool Presetter?

Investing in a tool presetter is essential for businesses seeking to improve their machining operations’ efficiency, accuracy, and productivity. The device will help you eliminate manual measurement errors, reduce downtime due to measurements, increase part quality, reduce scrap rates, and save costs over time.

A tool presetter is also an excellent investment for businesses looking to streamline their processes and stay competitive in today’s rapidly evolving manufacturing industry. With advanced automation technologies becoming increasingly common, manufacturers who fail to invest in modern equipment risk falling behind their competitors.

In Conclusion

A tool presetter is an essential device for precision machining operations. It allows machinists to accurately measure and set cutting tools outside of the machine, improving efficiency, accuracy, and productivity. Investing in a tool presetter can help you eliminate manual measurement errors, reduce downtime due to measurements, increase part quality, reduce scrap rates, and save costs over time.

If you’re looking to improve your manufacturing operations’ efficiency and stay competitive in today’s rapidly evolving industry, investing in a tool presetter is a smart choice.

References:

1. Tool presetters – Wikipedia. (n.d.). Retrieved May 28, 2021, from https://en.wikipedia.org/wiki/Tool_presetter

2. CNC Tool Presetters | BIG KAISER. (2021). Retrieved May 28, 2021, from https://www.bigkaiser.com/en/products/tool-measuring-systems/cnc-tool-presetters