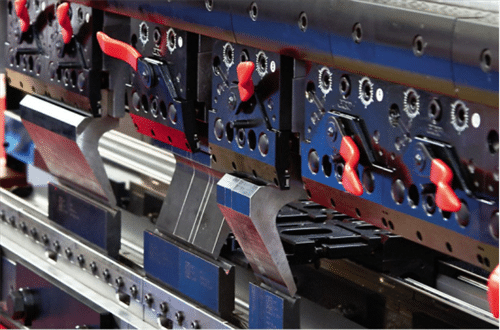

Amada press brake tooling is an essential component of any fabrication process. It is used to form metal sheets into various shapes and sizes, helping to create products that meet the needs of different industries. However, choosing and using the right tooling can be a daunting task, especially if you are new to the process.

In this article, we will take a comprehensive look at everything you need to know about Amada press brake tooling. From understanding the types of tools available to tips on choosing the right one for your machine, we have got you covered. So, let’s dive in!

Types of Amada Press Brake Tooling

Before we jump into how to choose and use Amada press brake tooling, it’s important to understand the different types available. Depending on your specific needs and requirements, there are four main types of tooling that you can choose from:

1. Punches – These are used to punch holes or slots into metal sheets. They come in various shapes and sizes, including round, square, rectangular, and oblong.

2. Dies – These are used to bend metal sheets into different angles and shapes. They come in various forms, including V-dies, U-dies, and acute angle dies.

3. Holders – These are used to hold the punches and dies in place during the bending process.

4. Accessories – These include items such as clamps and brackets that help to enhance the performance of your machine.

Now that we understand the different types of Amada press brake tooling let’s move onto how to choose the right one for your machine.

Tips on Choosing Amada Press Brake Tooling

Choosing the right Amada press brake tooling is crucial for achieving high-quality results in your fabrication process. Here are some tips on how to make the right choice:

1. Know Your Machine

The first step in choosing the right tooling is to know your machine’s capabilities and limitations. This includes understanding the tonnage, bed length, and stroke length of your press brake. Once you have this information, you can determine the type of tooling that will work best for your machine.

2. Consider The Material Being Bended

The material being bended plays a crucial role in selecting the right tooling. Different materials require different types of punches and dies. For instance, if you are bending stainless steel, you will need tooling made from high-speed steel or carbide.

3. Understand The Application

The application also plays a role in determining the type of tooling required. For instance, if you are producing parts with complex shapes or angles, you may need to use multiple dies or punches. On the other hand, if you are producing simple parts with straight bends, a single V-die may suffice.

4. Look For Quality

Investing in high-quality Amada press brake tooling is essential for achieving consistent and reliable results over time. Always look for suppliers who offer high-quality products that are durable and long-lasting.

Using Amada Press Brake Tooling: Best Practices

Now that we have covered how to choose Amada press brake tooling let’s move onto some best practices on using it effectively:

1. Set Up Properly

Proper setup is critical for achieving accurate results when using Amada press brake tooling. Ensure that all tools are aligned correctly and securely fastened before beginning the bending process.

2. Use The Right Tonnage

Using the correct tonnage is essential for preventing damage to your machine and minimizing wear on your tooling. Always refer to the manufacturer’s specifications when determining the correct tonnage for each job.

3. Lubricate Regularly

Lubrication helps to reduce friction between the tooling and the material being bent, thereby extending the life of your tools. Ensure that you lubricate your Amada press brake tooling regularly to prevent premature wear.

4. Inspect Regularly

Regular inspection of your Amada press brake tooling is essential for identifying any signs of damage or wear. This includes checking for cracks, chips, or burrs on your punches and dies.

Conclusion

Choosing and using the right Amada press brake tooling is crucial for achieving high-quality results in your fabrication process. By understanding the different types of tools available, tips on choosing the right one, and best practices on using it effectively, you can optimize your production process and minimize downtime. So, invest in high-quality Amada press brake tooling today and take your fabrication process to the next level!

References:

https://www.amadapressbrake.com/

https://www.metalformingmagazine.com/article/?/bending-/-forming/amada-s-innovative-press-brake-tooling

https://www.fabricatingandmetalworking.com/2018/04/amadas-high-performance-tooling-keeps-bend-quality-consistent-and-reliable/