In today’s fast-paced world, time is money. This is especially true in the manufacturing industry, where every second counts. One of the most effective ways to save time and streamline your workflow is by using composite tools.

Composite tools are specialized tools designed to work with composite materials, which are widely used in aerospace, automotive, and marine industries. These tools are critical to achieving high-quality results while minimizing production time and costs.

If you’re looking for ways to enhance your work efficiency, this guide will provide you with all the information you need about composite tools.

[h2]What Are Composite Materials?[/h2]

Before diving into composite tools, it’s essential to understand what composite materials are. Composite materials are made up of two or more different materials that are combined to form a material with superior properties.

The most common types of composite materials include carbon fiber reinforced polymer (CFRP), glass fiber reinforced polymer (GFRP), and aramid fiber reinforced polymer (AFRP). These materials offer exceptional strength-to-weight ratios, making them ideal for use in applications where weight reduction is crucial.

[h2]Why Use Composite Tools?[/h2]

Composite materials require specialized tools for cutting, drilling, sanding, and finishing. Traditional metalworking tools aren’t suitable for working with composite materials because they can cause delamination or damage to the material.

Using the right composite tool not only improves the quality of the finished product but also saves time and money by reducing waste and rework. Composite tools are designed to work specifically with composite materials, ensuring clean cuts, precise drilling holes, and smooth finishes.

[h2]Types of Composite Tools[/h2]

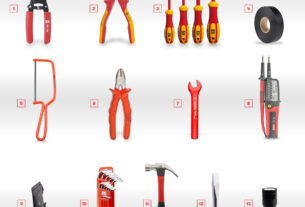

There are many different types of composite tools available on the market today. Some of the most commonly used ones include:

[ul]

[li][h2]Composite Cutting Tools[/h2]: These tools are designed to cut through composite materials with precision and accuracy. They come in various forms, including circular saw blades, jigsaw blades, and carbide-tipped router bits.[/li]

[li][h2]Composite Drilling Tools[/h2]: Composite drilling tools are designed to drill through composite materials without causing delamination or damage. They come in various shapes and sizes, including twist drills, countersinks, and step drills.[/li]

[li][h2]Composite Sanding Tools[/h2]: Sanding composite materials requires specialized tools designed to prevent damage or delamination. Sanding tools include sandpaper, sanding blocks, and orbital sanders.[/li]

[li][h2]Composite Finishing Tools[/h2]: Composite finishing tools are used to achieve a smooth finish on the surface of composite materials. These tools include buffing pads, polishing compounds, and wax applicators.[/li]

[/ul]

[h2]Choosing the Right Composite Tool[/h2]

Choosing the right composite tool depends on several factors, including the type of composite material you’re working with and the specific task you need to perform.

When selecting a composite tool, consider the material’s thickness and hardness as well as the required cutting speed and feed rate. For example, if you’re working with thick carbon fiber reinforced polymer (CFRP), you’ll need a high-speed cutting tool that can handle the material’s hardness.

It’s also essential to choose a tool that matches your machine’s specifications. Ensure that the tool’s shank diameter matches your machine’s collet size to avoid compatibility issues.

[h2]Maintaining Your Composite Tools[/h2]

To ensure your composite tools remain in good condition and provide optimal performance, proper maintenance is critical. Here are some tips for maintaining your composite tools:

[ul]

[li]Clean your tools after every use to remove any dust or debris that could affect their performance.[/li]

[li]Regularly sharpen your cutting tools to ensure they remain sharp and effective.[/li]

[li]Store your tools in a dry, cool place to prevent rust and corrosion.[/li]

[li]Replace any worn or damaged tools promptly to avoid damage to the composite material or machine.[/li]

[/ul]

[h2]Conclusion[/h2]

In conclusion, using the right composite tool is essential for enhancing work efficiency in the manufacturing industry. Composite materials require specialized tools designed to prevent damage while ensuring clean cuts, precise drilling holes, and smooth finishes.

When choosing a composite tool, consider the specific task and the composite material’s thickness and hardness. Proper maintenance of your composite tools will ensure optimal performance and longevity.

If you’re looking for high-quality composite tools, there are many reputable suppliers to choose from. Check out websites like Composites One, ACS Composite Solutions, and Fibre Glast for more information.

References:

– https://en.wikipedia.org/wiki/Composite_material

– https://www.acscomposites.com/

– https://www.fibreglast.com/

– https://www.compositesone.com/