If you’re a fan of outdoor power equipment, chances are you’ve had to deal with small engine repairs at some point. Whether it’s a lawnmower that won’t start or a chainsaw that needs a tune-up, having the right tools on hand can make all the difference. In this article, we’ll take a closer look at some of the essential small engine tools every DIY mechanic should have in their toolbox.

H2: What Are Small Engine Tools?

Before we dive into the specifics, let’s define what we mean by “small engine tools.” These are specialized tools designed for working on engines typically found in outdoor power equipment such as lawnmowers, chainsaws, and leaf blowers. Unlike automotive engines, which tend to be larger and more complex, small engine repairs often require precision work done in tight spaces.

H2: Essential Small Engine Tools

Now that we know what we’re talking about let’s take a look at some of the most important small engine tools you’ll need for basic repairs and maintenance.

Spark Plug Wrench

A spark plug wrench is an essential tool for changing out old or fouled spark plugs. These wrenches come in various sizes depending on the type of spark plug you’re working with. A good spark plug wrench should have a rubber grip for added comfort and leverage.

Feeler Gauge

A feeler gauge is a thin strip of metal used to measure gaps between two surfaces. In small engine repairs, feeler gauges are commonly used to set the gap between the ignition coil and the flywheel. They come in different thicknesses, so be sure to choose one that matches your machine’s specifications.

Piston Ring Compressor

When rebuilding an engine, you’ll need to install new piston rings. A piston ring compressor makes this job much easier by compressing the rings and allowing you to slide the piston into the cylinder. Look for a compressor that’s adjustable to fit different size pistons.

Valve Spring Compressor

A valve spring compressor is used to remove and install valve springs in an engine. This tool compresses the spring, allowing you to remove the keepers and release the tension on the valve. Choose a compressor with a sturdy frame and comfortable grip.

Torque Wrench

A torque wrench is a critical tool for ensuring that bolts are tightened to the correct specifications. Over-tightening bolts can damage threads or even crack engine components, while under-tightening can lead to leaks or other issues. A good torque wrench should be easy to read and have a wide range of torque settings.

H2: Other Useful Small Engine Tools

In addition to the tools we’ve already mentioned, there are several others that can come in handy when working on small engines:

– Carburetor cleaner: Used to clean out clogged carburetors

– Compression tester: Measures engine compression to diagnose problems

– Flywheel puller: Removes the flywheel from the crankshaft for repairs

– Ignition tester: Checks for spark in ignition systems

– Oil filter wrench: Makes it easier to remove stubborn oil filters

H2: Tips for Using Small Engine Tools

Now that you have an idea of what kind of tools you need let’s look at some tips for using them effectively:

– Always use the right tool for the job: Trying to make do with a makeshift tool can lead to mistakes or damage.

– Keep your tools organized: A cluttered toolbox can make it hard to find what you need when you need it.

– Follow manufacturer instructions: Consult your machine’s owner’s manual for specific repair instructions and torque specifications.

– Wear safety gear: When working with power equipment, always wear eye protection, gloves, and other appropriate safety gear.

H2: Conclusion

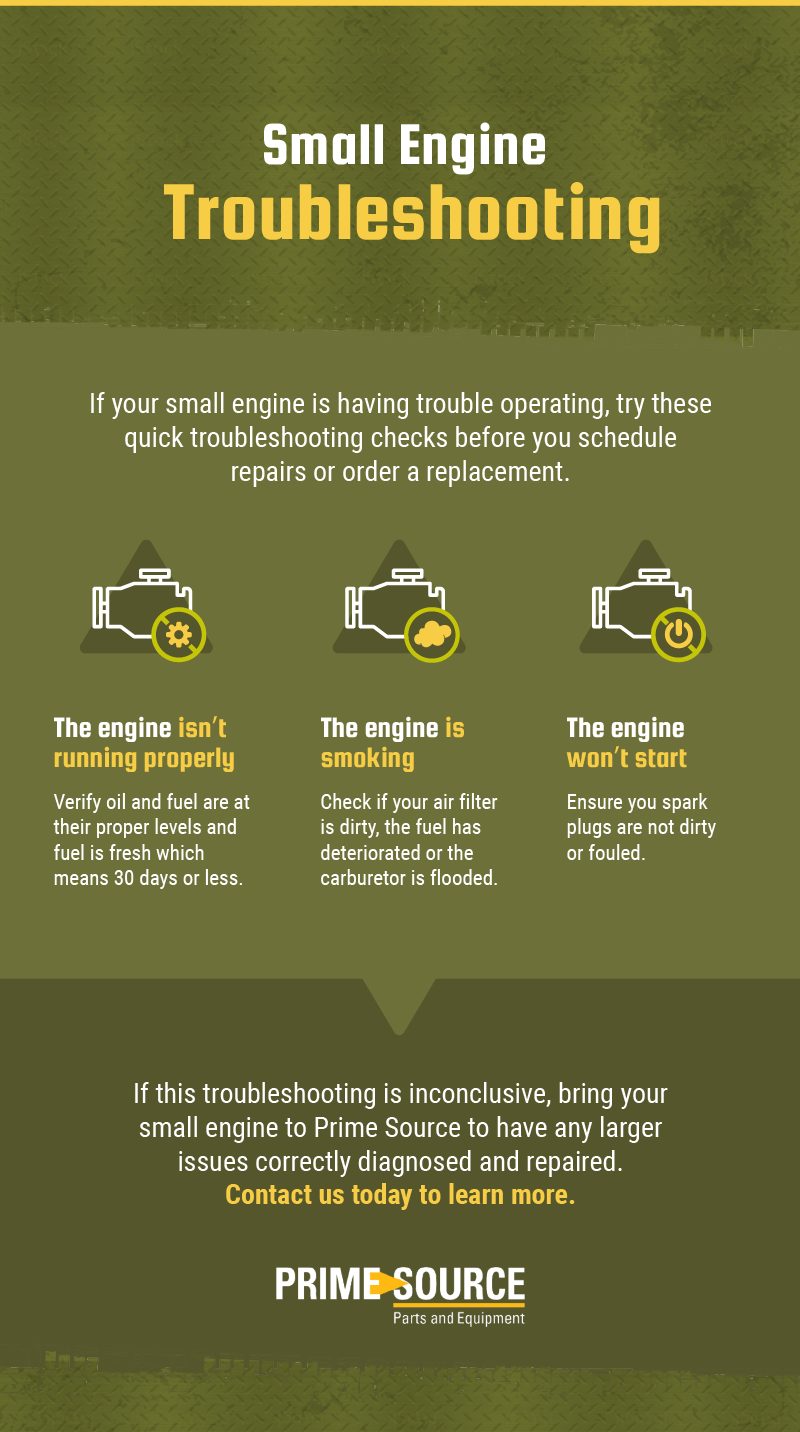

Small engine repairs can be frustrating, but having the right tools on hand can make a world of difference. By investing in high-quality small engine tools and taking the time to learn how to use them correctly, you can keep your outdoor power equipment running smoothly for years to come.

Wiki Reference: https://en.wikipedia.org/wiki/Small_engine