As a professional editor for SEO, I have come across various tools and equipment that are used in different industries. However, one tool that stands out is the molder tool. If you are an engineer or work in the manufacturing industry, then you know how important this tool is. In this comprehensive guide, we will take a closer look at what a molder tool is, how it works, and its applications.

What Is a Molder Tool?

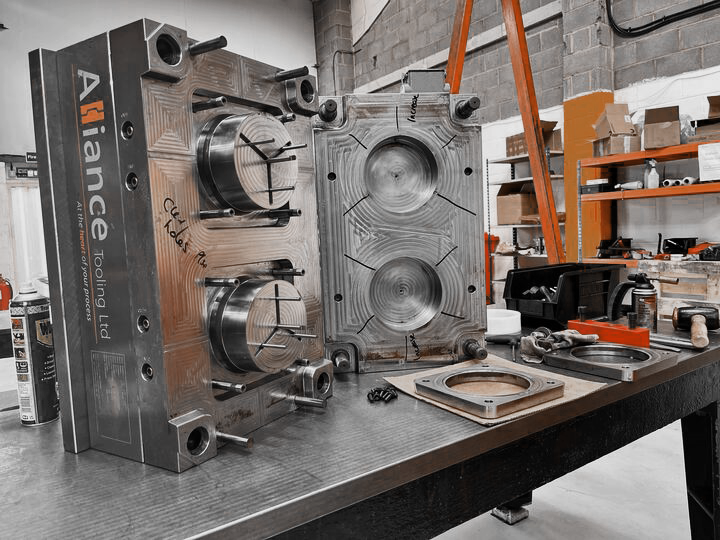

A molder tool is a machine that is used to shape plastic or metal parts by injecting them into a mold. This process is also known as injection molding. The machine consists of two main parts: the injection unit and the clamping unit.

The injection unit is responsible for melting and injecting the material into the mold. The clamping unit holds the mold together during the injection process. Once the material has been injected into the mold, it cools and solidifies to form the desired part.

How Does a Molder Tool Work?

The first step in using a molder tool is to select the appropriate mold for your application. The mold can be made from various materials such as steel, aluminum, or copper. Once you have selected the mold, it is mounted onto the clamping unit of the machine.

Next, the material that you want to inject into the mold is loaded into the injection unit. The material can be in pellet or powder form depending on your preference. The injection unit heats up the material until it melts and becomes viscous.

Once the material has melted, it is injected into the mold under high pressure. The pressure ensures that the material fills all parts of the mold evenly. After injecting the material, it is left to cool and solidify inside the mold.

When the part has cooled down sufficiently, it can be removed from the mold using ejector pins. Ejector pins are small rods that push the part out of the mold. The part can then be trimmed and finished to achieve the desired shape.

Applications of Molder Tools

Molder tools are used in various industries such as automotive, medical, and consumer goods. They are used to produce parts with complex shapes and high precision. Some common applications of molder tools include:

1. Automotive Parts: Molder tools are used to produce various parts for cars such as dashboards, bumpers, and interior trims.

2. Medical Devices: Molder tools are used to produce medical devices such as syringes, catheters, and IV bags.

3. Consumer Goods: Molder tools are used to produce everyday items such as toys, household appliances, and electronics.

Advantages of Using a Molder Tool

1. High Precision: Molder tools can produce parts with high precision and accuracy. This is because the material is injected into the mold under high pressure, ensuring that it fills all parts of the mold evenly.

2. Cost-Effective: Molder tools can produce large quantities of parts quickly and cost-effectively. This makes them ideal for mass production.

3. Versatile: Molder tools can be used to produce parts with a wide range of shapes and sizes. This makes them suitable for various industries.

4. Reduced Waste: Molder tools produce less waste compared to other manufacturing methods such as CNC machining or 3D printing.

Conclusion

In conclusion, molder tools are essential machines in the manufacturing industry. They are used to produce parts with high precision and accuracy while being cost-effective and versatile. Understanding how they work and their applications will help you make informed decisions when choosing a manufacturing method for your project.

References:

https://www.thomasnet.com/articles/custom-manufacturing-fabricating/injection-molding-process/

https://www.creativemechanisms.com/blog/everything-you-need-to-know-about-injection-molding

https://www.ptonline.com/articles/applications-medical

https://www.autonews.com/article/20191017/OEM10/191019892/five-trends-shaping-the-future-of-plastics-in-automotive