Are you struggling with optimizing your automotive manufacturing efficiency? Look no further than AME tools! With the latest technological advancements in the industry, these innovative tools are designed to optimize every aspect of your manufacturing process. From reducing downtime to improving quality control, AME tools have revolutionized the automotive manufacturing industry.

In this ultimate guide, we will explore everything you need to know about AME tools and how they can benefit your business. So, buckle up and get ready for a whirlwind tour of the world of AME tools!

What Are AME Tools?

AME (Advanced Manufacturing Engineering) tools refer to a set of cutting-edge technologies used in the automotive manufacturing industry. These tools are designed to improve production efficiency, reduce costs and enhance quality control. They are typically used by manufacturers of automobiles, aircraft, and other heavy equipment.

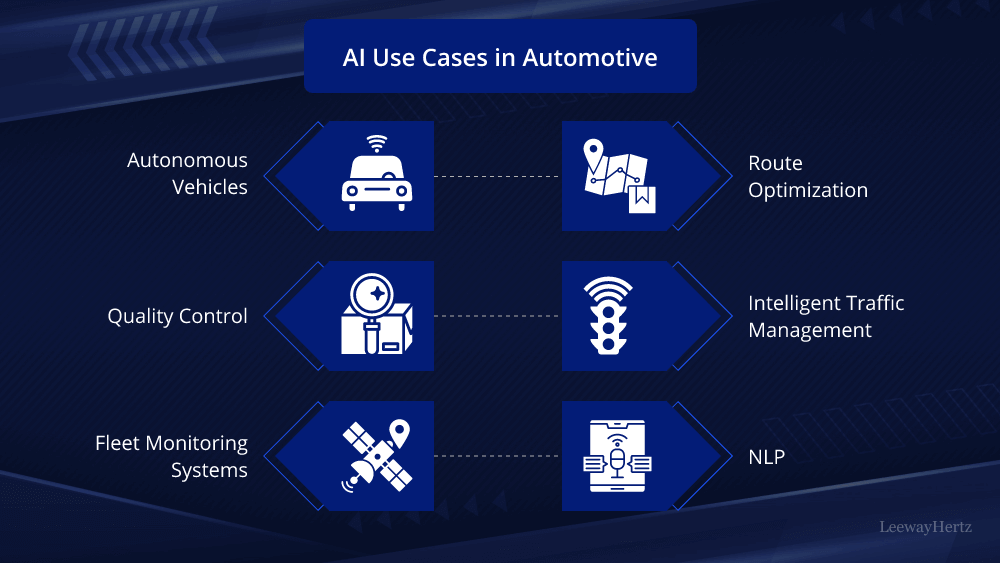

Some examples of AME tools include robotics, automation systems, digital twin technology, 3D printing, and artificial intelligence. These technologies work together to streamline the manufacturing process from start to finish.

The Benefits of Using AME Tools

Now that we understand what AME tools are let’s take a closer look at their benefits:

1. Increased Efficiency: By automating certain tasks and incorporating robotics into the manufacturing process, AME tools can significantly increase efficiency and productivity. This means more output in less time.

2. Improved Quality Control: With the help of advanced sensors and monitoring systems, AME tools can detect defects or errors early on in the production process, leading to fewer mistakes and higher quality products.

3. Cost Reduction: By optimizing various aspects of the manufacturing process, such as material handling or part assembly, AME tools can help reduce overall production costs.

4. Flexibility: One of the most significant benefits of using AME tools is their flexibility. These technologies can be easily adapted to different manufacturing processes, allowing manufacturers to customize their production lines according to their specific needs.

Types of AME Tools

Now that we’ve explored the benefits of using AME tools let’s take a look at some of the most commonly used types:

1. Robotics: Robotics is one of the most widely used AME tools in the automotive manufacturing industry. Robots can be programmed to perform a variety of tasks, from welding and painting to assembly and material handling.

2. Automation Systems: Automation systems are designed to automate repetitive tasks and streamline production processes. They can include conveyor belts, sorting systems, and assembly machines.

3. Digital Twin Technology: Digital twin technology is a simulation tool that allows manufacturers to create a virtual replica of their production line. This helps them identify potential issues before they occur and optimize their processes for maximum efficiency.

4. 3D Printing: 3D printing is a process where physical objects are created by laying down successive layers of materials until the desired shape is achieved. This technology has revolutionized prototyping and small-scale production in the automotive industry.

5. Artificial Intelligence: Artificial intelligence (AI) is an emerging field in the AME toolset. AI can be used to analyze data from sensors and other monitoring systems to detect patterns and predict issues before they occur.

How to Choose the Right AME Tool for Your Business

Choosing the right AME tool for your business depends on several factors, including your specific manufacturing needs, budget, and current production processes. Here are some key considerations when selecting an AME tool:

1. Identify Your Manufacturing Needs: Consider what areas of your production process could benefit from automation or optimization. Do you need help with material handling or assembly? Are you struggling with quality control?

2. Research Available Technologies: Once you’ve identified your manufacturing needs, research available technologies that can address those needs. Look for case studies or success stories from other companies in your industry to help guide your decision.

3. Consider Your Budget: AME tools can be expensive, so consider your budget when selecting a technology. Look for technologies that offer the most significant return on investment (ROI) and factor in ongoing maintenance costs.

4. Evaluate Compatibility with Existing Processes: Consider how the new technology will integrate with your existing production processes. Will you need to retrain employees? Will there be any downtime during installation?

Conclusion

AME tools are revolutionizing the automotive manufacturing industry by improving efficiency, reducing costs, and enhancing quality control. With the latest innovations in robotics, automation systems, digital twin technology, 3D printing, and artificial intelligence, manufacturers have never had more options to optimize their production lines. When considering which AME tool to use, it is important to identify your specific manufacturing needs and evaluate available technologies based on cost, compatibility with existing processes, and potential ROI.

References:

1. https://www.forbes.com/sites/forbestechcouncil/2019/04/22/how-ame-will-transform-the-manufacturing-industry/?sh=7aebd6fc6f5e

2. https://www.thomasnet.com/articles/custom-manufacturing-fabricating/advantages-of-advanced-manufacturing-engineering-ame-tools/

3. https://www.mckinsey.com/business-functions/operations/our-insights/the-next-generation-of-manufacturing-technologies#