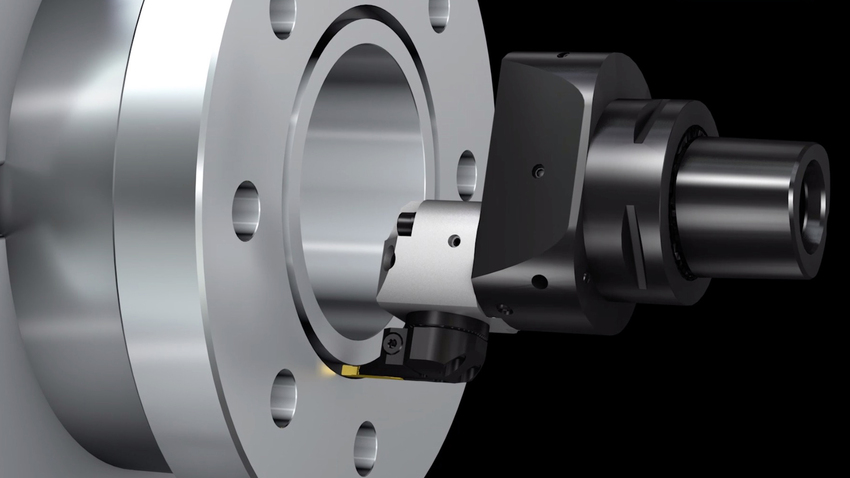

If you’re in the machining industry, you know how important it is to have the right tools for the job. One of the most crucial tools in your arsenal is the face grooving tool. This versatile tool can help you create precision grooves and contours on a variety of materials, including metal, plastic, and wood. In this article, we’ll explore everything you need to know about face grooving tools and how they can take your machining skills to the next level.

What is a Face Grooving Tool?

A face grooving tool is a cutting tool that’s used to create grooves or contours on the surface of a workpiece. These tools are commonly used in turning applications and are designed to fit into a lathe or other similar machine. They typically feature a flat cutting edge that’s perpendicular to the shank of the tool, which allows them to make precise cuts at varying depths.

Types of Face Grooving Tools

There are several different types of face grooving tools available on the market today, each with its own unique design and features. Some of the most common types include:

1. Square Shoulder Face Grooving Tools – These tools feature a square shoulder design that allows them to create sharp corners in grooves or contours.

2. Round Nose Face Grooving Tools – With a rounded nose, these tools are ideal for creating smooth curves and contours on workpieces.

3. Cut-Off Face Grooving Tools – These specialized tools are designed specifically for cutting off sections of material from a workpiece.

4. Threading Face Grooving Tools – Used primarily for creating threads on screws and bolts, these tools feature a V-shaped groove that helps guide the cutting process.

How to Choose the Right Face Grooving Tool

Choosing the right face grooving tool for your project depends on several factors, including:

1. Material Type – Different materials require different types of cutting tools. Make sure you choose a tool that’s designed to work with the material you’re machining.

2. Depth of Cut – Consider how deep the grooves or contours need to be and choose a tool that can handle that depth of cut.

3. Tool Holder Type – The type of tool holder you’re using will also impact your choice of face grooving tool.

4. Cutting Speeds and Feeds – Make sure you choose a tool that’s capable of handling the cutting speeds and feeds required for your project.

Tips for Using Face Grooving Tools

To get the most out of your face grooving tools, keep these tips in mind:

1. Always use the right type of tool for the job.

2. Make sure your tool is properly aligned and secured in the machine before you start cutting.

3. Use the appropriate cutting speed and feed rate for the material you’re working with.

4. Keep your tools sharp and well-maintained to ensure precision cuts every time.

5. Use lubrication or coolant to prevent overheating and extend the life of your tools.

Conclusion

Face grooving tools are an essential part of any machining toolkit, allowing you to create precise grooves and contours on a variety of materials. By choosing the right tool for the job and following best practices when it comes to cutting speeds, feeds, and maintenance, you can achieve professional-grade results every time.

References:

1. “Face Grooving Tool,” Wikipedia, https://en.wikipedia.org/wiki/Face_grooving_tool

2. “Machining Basics: Face Grooving Tools,” Modern Machine Shop, https://www.mmsonline.com/articles/machining-basics-face-grooving-tools