If you’re in the market for a grease zerk tool, you’ve come to the right place. Grease zerks, also known as grease fittings, are essential components of most machinery and equipment that require lubrication. These fittings allow for easy access to lubrication points and ensure proper distribution of grease throughout the system.

In this guide, we’ll delve into everything you need to know about grease zerk tools, including their functions, types, and best practices for maintenance. Let’s get started!

Understanding the Function of a Grease Zerk Tool

A grease zerk tool is a small fitting that connects to a lubrication point on machinery or equipment. It allows for easy access to the area that requires lubrication so that grease can be distributed effectively. Without this tool, it would be challenging to apply lubricant accurately.

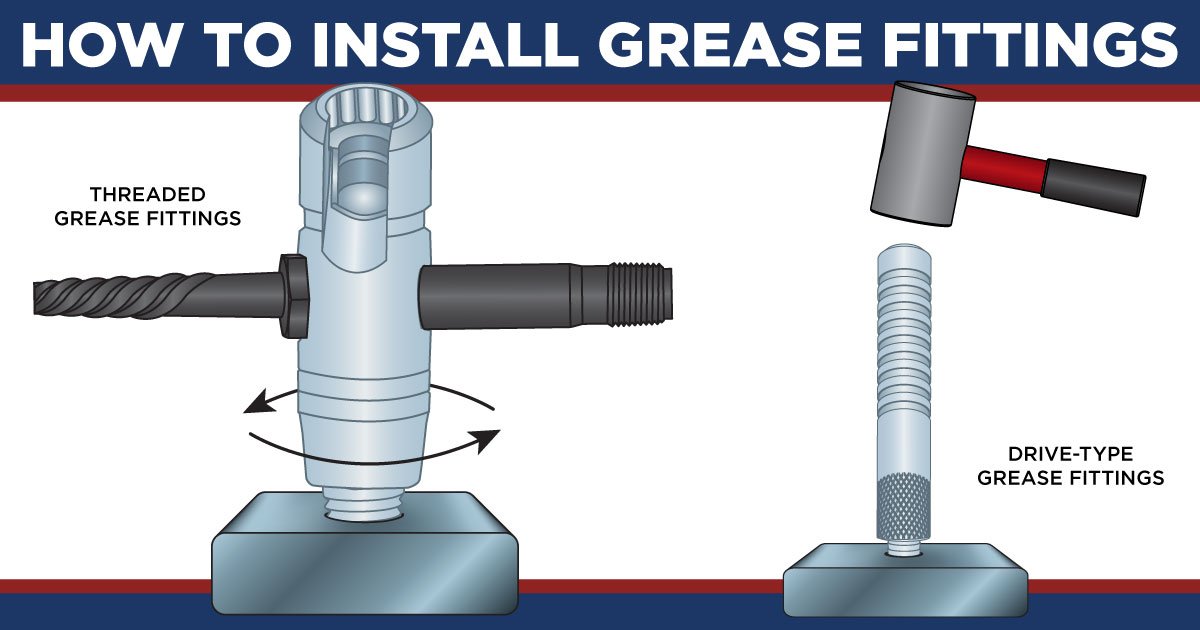

There are several types of grease fittings available, including straight fittings, angled fittings, button head fittings, flush fittings, and more. Each type serves a specific purpose and is designed to fit different applications. For example, flush fittings are ideal for low-clearance applications where space is limited.

The Importance of Proper Lubrication Techniques

Proper lubrication techniques are critical to ensuring the longevity and efficiency of your machinery or equipment. When machines don’t receive proper maintenance, they can experience wear and tear faster than usual, leading to costly repairs or replacements.

Using a grease zerk tool is one way to ensure that your machinery receives adequate lubrication. However, it’s essential to follow best practices when using this tool and applying lubricant.

Best Practices for Using a Grease Zerk Tool

To use a grease zerk tool correctly, follow these steps:

1. Identify the location of the lubrication point: Before applying any lubricant, locate the grease fitting on your machinery or equipment.

2. Clean the area around the fitting: Use a clean rag or wire brush to remove any debris or dirt around the lubrication point. This will prevent contamination of the grease and ensure proper application.

3. Attach the grease zerk tool: Attach the grease zerk tool to the fitting and secure it in place.

4. Apply the lubricant: Squeeze the trigger on your grease gun to apply lubricant to the fitting. Make sure to apply enough grease, but don’t overdo it as this can cause damage.

5. Remove the grease zerk tool: Once you’ve applied sufficient lubricant, remove the grease zerk tool from the fitting.

6. Wipe away any excess grease: Use a clean cloth to wipe away any excess grease around the lubrication point.

By following these best practices, you’ll ensure that your machinery receives adequate lubrication and runs smoothly for years to come.

Types of Grease Zerk Tools

There are several types of grease zerk tools available, each designed for different applications. Some common types include:

1. Straight fittings: These fittings are ideal for standard applications where there is sufficient clearance space.

2. Angled fittings: These fittings have an angled design that makes it easier to access hard-to-reach areas.

3. Button head fittings: These fittings have a button-shaped head that allows for easy installation and removal.

4. Flush fittings: These fittings are ideal for low-clearance applications where space is limited.

5. Drive-type fittings: These fittings require a special tool to install and remove them, making them more secure than other types of fittings.

Choosing the right type of grease zerk tool will depend on your specific application and equipment requirements.

Maintenance Tips for Your Grease Zerk Tool

To ensure that your grease zerk tool continues to function optimally, follow these maintenance tips:

1. Keep it clean: After each use, wipe down your grease zerk tool with a clean cloth to remove any excess lubricant or debris.

2. Store it properly: When not in use, store your grease zerk tool in a clean, dry place to prevent contamination.

3. Check for damage: Regularly inspect your grease zerk tool for any signs of damage or wear and tear. Replace it if necessary.

4. Use the right lubricant: Always use the recommended type of lubricant for your equipment and application. Using the wrong type can cause damage and affect performance.

By following these maintenance tips, you’ll extend the life of your grease zerk tool and ensure that it continues to function optimally.

In Conclusion

A grease zerk tool is an essential component of most machinery and equipment that require lubrication. By understanding its functions, types, and best practices for maintenance, you can ensure that your machinery receives adequate lubrication and runs smoothly for years to come.

Remember to choose the right type of grease fitting for your application, follow best practices when using it, and maintain it regularly. With proper care and attention, your grease zerk tool will continue to serve you well for many years.

References:

1. https://en.wikipedia.org/wiki/Grease_fitting

2. https://www.machinerylubrication.com/Read/30817/grease-fittings

3. https://www.northerntool.com/shop/tools/category_lubrication+grease-fittings