If you’re a machinist or a DIY enthusiast, you know the importance of having a reliable lathe threading tool. It’s an essential tool used for cutting threads on metal surfaces and creating screws that fit perfectly into threaded holes. But with so many options available in the market, choosing the right one can be overwhelming. In this article, we’ll guide you through everything you need to know about lathe threading tools.

[h2]What is a Lathe Threading Tool?[/h2]

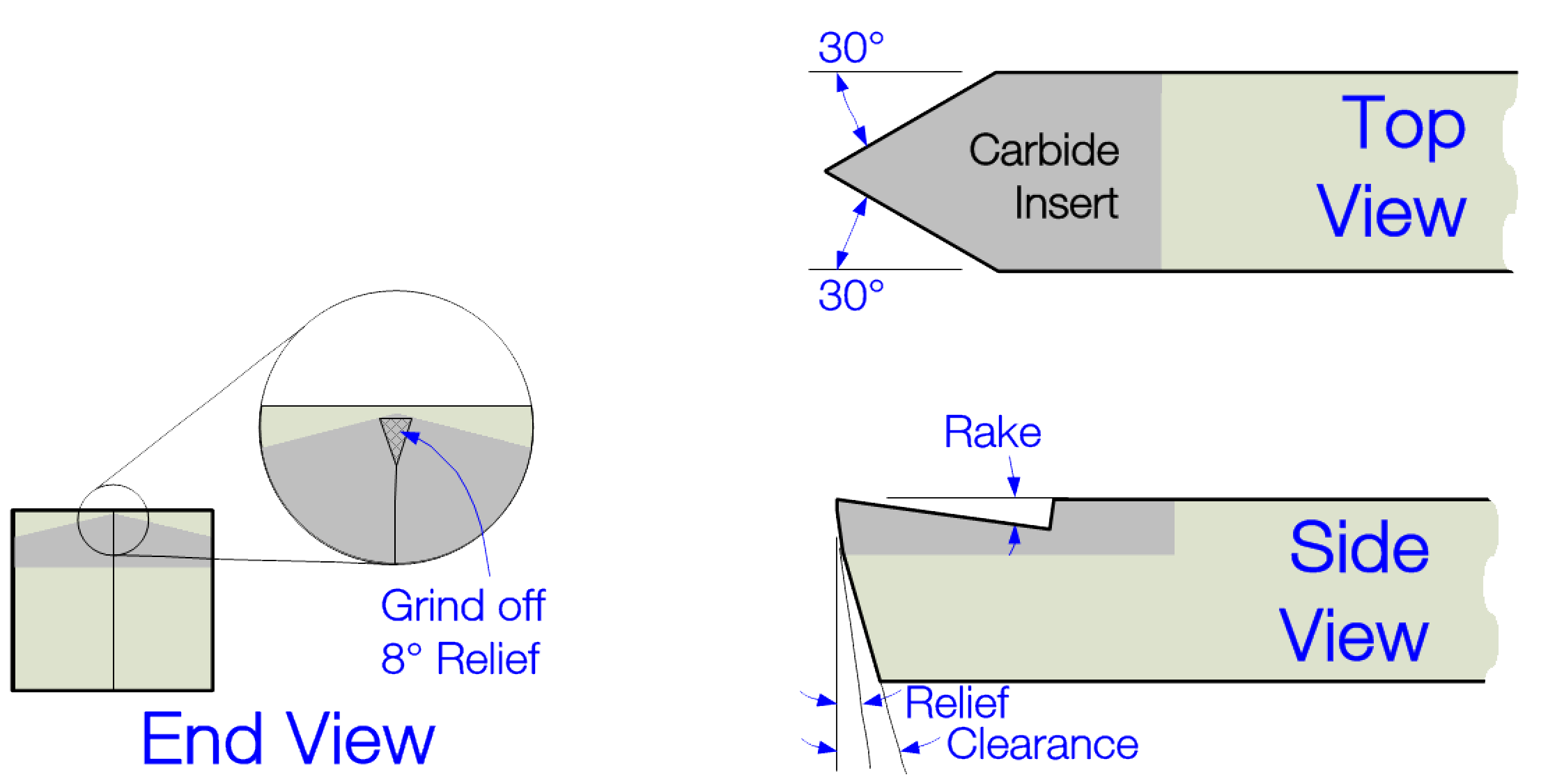

A lathe threading tool is a cutting tool used to create external and internal threads on cylindrical surfaces. It consists of a specially designed cutting edge mounted on a shank that fits into a lathe machine’s tool post. The cutting edge is usually made of high-speed steel or carbide and has a specific shape that allows it to cut threads accurately.

[h2]Types of Lathe Threading Tools[/h2]

There are several types of lathe threading tools available, each with its unique features and benefits. Let’s take a look at some of the most common types:

1. Single Point Thread Cutting Tool: This type of threading tool has only one cutting edge and is used for cutting external threads on cylindrical surfaces.

2. Internal Thread Cutting Tool: As the name suggests, this type of tool is used for cutting internal threads on cylindrical surfaces.

3. Forming Thread Cutting Tool: A forming thread cutting tool is used to create threads by compressing the material instead of removing it.

4. Inserted Tip Threading Tool: An inserted tip threading tool has replaceable inserts that allow you to change the cutting edge without replacing the entire tool.

[h2]How to Choose the Right Lathe Threading Tool[/h2]

Choosing the right lathe threading tool requires careful consideration of various factors such as material, thread pitch, and thread size. Here are some tips to help you choose the right tool for your needs:

1. Material: The material of the workpiece you’re cutting will determine the type of threading tool you need. For softer materials such as aluminum, a high-speed steel threading tool is suitable. But for harder materials like stainless steel, a carbide threading tool is preferable.

2. Thread Pitch: The thread pitch refers to the distance between each thread on a screw or bolt. It’s crucial to choose a threading tool that matches the thread pitch you need.

3. Thread Size: The thread size is another critical factor to consider when choosing a lathe threading tool. Make sure you choose a tool that can handle the thread size you need.

[h2]How to Use a Lathe Threading Tool[/h2]

Using a lathe threading tool requires skill and precision. Here’s a step-by-step guide on how to use it:

1. Set up your lathe machine and ensure it’s in good working condition.

2. Select the appropriate threading tool based on the material, thread pitch, and thread size.

3. Mount the threading tool onto the lathe machine’s tool post.

4. Position the workpiece in the lathe machine using a chuck or collet.

5. Adjust the lathe’s speed and feed rate according to the material being cut.

6. Engage the threading tool into the workpiece using the cross-slide and carriage controls.

7. Turn the handwheel slowly to start cutting threads into the workpiece.

8. Check your progress frequently using a thread gauge until you’ve achieved the desired thread depth and pitch.

[h2]Conclusion[/h2]

In conclusion, choosing and using a lathe threading tool requires careful consideration of various factors such as material, thread pitch, and thread size. By following our guide, you’ll be able to select and use a threading tool that meets your needs and produces high-quality threads.

References:

1. https://en.wikipedia.org/wiki/Lathe_cutting_tools

2. https://www.machiningcloud.com/applications/lathe-tools-threading-tools/

3. https://www.cnccookbook.com/thread-cutting-cnc-lathe-using-g-code/