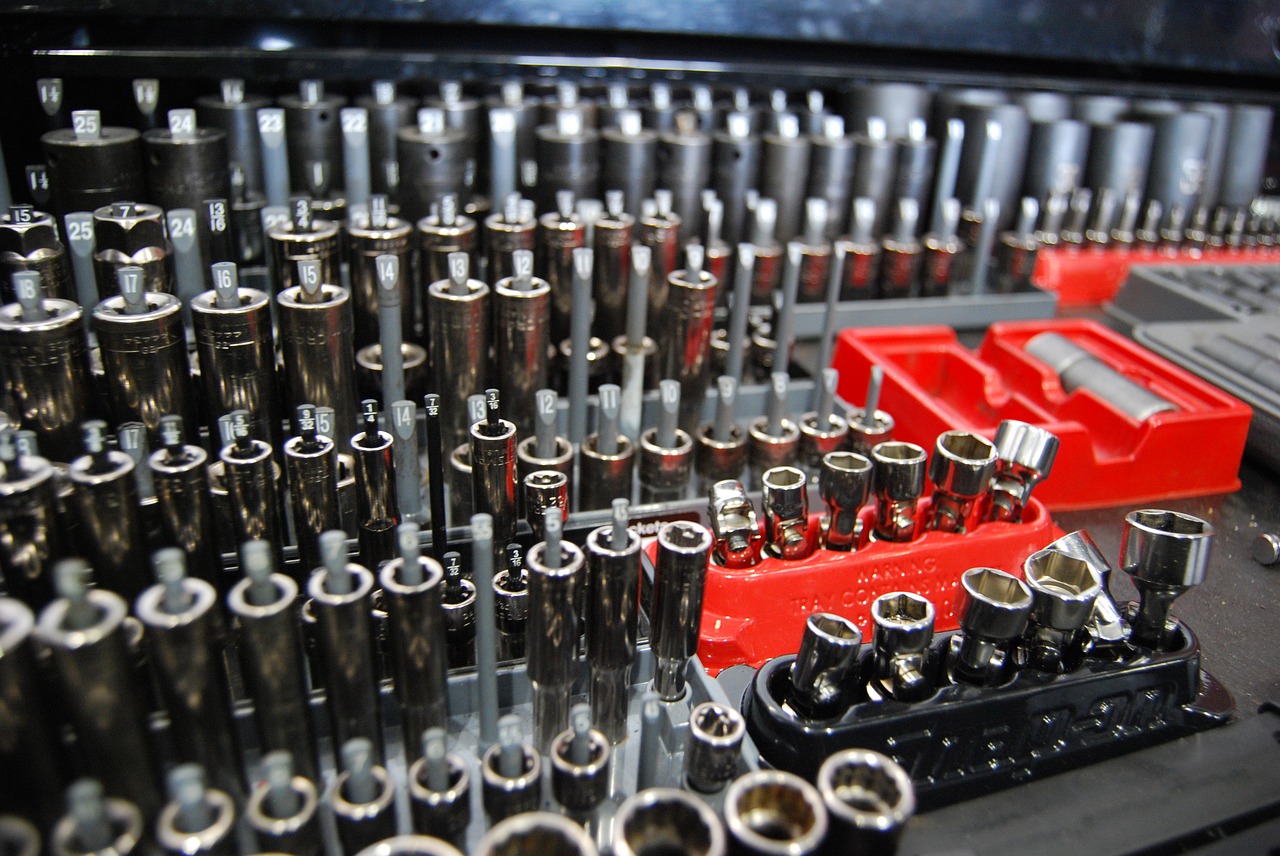

As a millwright, your tool box is your best friend. It contains all of the essential tools that you need to get the job done right. But what exactly should be in your tool box? In this article, we’ll take a look at everything you need to know about the millwright tool box.

[h2]What is a Millwright Tool Box?[/h2]

A millwright tool box is essentially a collection of tools that are used by millwrights. These tools are specifically chosen based on their usefulness for the tasks that millwrights do, such as installing and maintaining machinery and equipment.

[h2]Essential Tools for Your Millwright Tool Box[/h2]

1. Wrenches: Wrenches are an essential tool for any millwright. They come in different sizes and shapes, so it’s important to have a variety of them in your toolbox.

2. Pliers: Pliers are another must-have tool for any millwright. They can be used for gripping and twisting wires, cutting cables, and even pulling out nails.

3. Screwdrivers: Screwdrivers are necessary for tightening or loosening screws on various machines and equipment.

4. Hammers: Hammers are needed for both light and heavy-duty tasks such as tapping bearings into place or breaking apart rusted bolts.

5. Levels: Levels help ensure that everything is straight and level during installation or repair work.

6. Measuring tapes: Accurate measurements are crucial when working with machinery or equipment, making measuring tapes an indispensable part of any millwright’s toolkit.

7. Safety glasses: Eye protection is essential when working with power tools or in hazardous environments.

8. Gloves: Gloves protect hands from cuts, abrasions, chemicals, and other hazards on the job site.

9. Flashlights: Flashlights are useful for working in dark areas or tight spaces where light is limited.

[h2]Other Tools to Consider[/h2]

1. Pipe wrenches: If you work with pipes, pipe wrenches can be a helpful addition to your tool box.

2. Torque wrenches: These tools help ensure that bolts are tightened to the correct torque specifications.

3. Wire strippers: For tasks such as electrical wiring, wire strippers make it easy to remove insulation without damaging the wire.

4. Angle grinders: Angle grinders can be used for cutting, grinding, and polishing metal or other materials.

[h2]Organization is Key[/h2]

When it comes to organizing your millwright tool box, there’s no one-size-fits-all solution. However, keeping your tools organized and easily accessible can save you time and frustration on the job site. Here are some tips:

1. Use a tool bag or toolbox: A sturdy bag or toolbox will protect your tools from damage and make them easier to transport.

2. Label everything: Labeling each tool with its name or function makes it easier to find what you’re looking for quickly.

3. Use foam inserts: Foam inserts cut specifically for each tool can hold them securely in place and protect them from damage.

4. Keep order in mind: Arrange your tools in an order that makes sense to you so that you don’t have to waste time searching for specific items.

[h2]Conclusion[/h2]

A well-stocked and organized millwright tool box is essential for any millwright’s success on the job site. By having all of the necessary tools at hand, you can complete jobs quickly and efficiently while maintaining high standards of safety and quality.

References:

– https://en.wikipedia.org/wiki/Millwright

– https://www.osha.gov/SLTC/millwrights/tools.html