Are you in search of high-quality industrial cutting tools for your business? Look no further than North American Tool, the leading manufacturer of precision threading and grooving solutions.

With over 30 years of experience in the industry, North American Tool offers a wide range of products that cater to different applications. Whether you’re in the automotive, aerospace, medical, or oil and gas industry, their cutting tools are designed to meet your specific needs.

In this article, we’ll delve deeper into what makes North American Tool stand out from the competition. We’ll explore their product line-up, highlight their innovative solutions, and provide tips on how to choose the right cutting tool for your business.

So, let’s get started!

[h2]What Makes North American Tool Unique?[/h2]

North American Tool has established itself as a pioneer in the industrial cutting tool market. Their products are known for their exceptional quality and performance, making them a popular choice among businesses worldwide.

Here are some key factors that set North American Tool apart from other manufacturers:

– Precision Engineering: All of North American Tool’s products undergo rigorous testing and inspection to ensure they meet the highest standards of precision and accuracy. This attention to detail ensures that their cutting tools perform consistently across various applications.

– Custom Solutions: North American Tool understands that each business has unique requirements when it comes to cutting tools. That’s why they offer customized solutions tailored to your specific needs. From designing special coatings to developing custom inserts, they can help you achieve maximum productivity and efficiency.

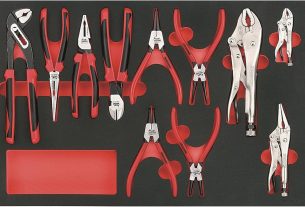

– Robust Product Line-Up: With a vast selection of threading and grooving solutions available, North American Tool has something for every application. From standard taps and dies to micro-threading tools and specialty cutters, they have you covered.

[h2]North American Tool Products[/h2]

North American Tool’s product line-up is extensive, covering a wide range of applications. Here’s a breakdown of their products:

– Taps: North American Tool offers a comprehensive selection of taps for every type of material and application. Their taps are designed to provide maximum chip evacuation, reduce tool wear, and improve thread quality.

– Dies: Their dies are made from high-quality materials and feature precision-ground threads that produce accurate and consistent results. They offer dies for external and internal threading, as well as round and hexagon shapes.

– Thread Mills: North American Tool’s thread mills are designed to create precise threads in a single pass. They offer both solid carbide and indexable options, making them suitable for various materials.

– Micro Tools: For applications that require small diameter threading or grooving, North American Tool offers micro tools with diameters as small as 0.004 inches. These tools are ideal for the medical and electronics industries.

– Specialty Cutters: From chamfer cutters to form tools, North American Tool has a range of specialty cutters that cater to specific applications. These cutters are designed to increase productivity while maintaining accuracy and precision.

[h2]Innovative Solutions[/h2]

North American Tool is known for its innovative solutions that enhance productivity and efficiency. Here are some examples:

– Reamers with Coolant Through Holes: These reamers feature coolant through holes that deliver coolant directly to the cutting edge. This improves chip evacuation, reduces heat buildup, and extends tool life.

– Carbide Inserts with Proprietary Coatings: North American Tool offers carbide inserts with special coatings that enhance performance and durability. The coatings reduce friction, prevent chip welding, and improve wear resistance.

– Quick Change Tap Adapters: These adapters allow you to change tap sizes quickly without the need for additional tooling. This saves time and increases productivity.

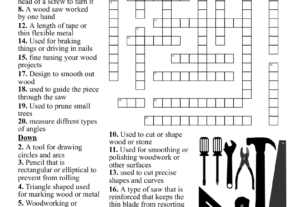

[h2]Choosing the Right Cutting Tool[/h2]

Choosing the right cutting tool is essential to achieving optimal results. Here are some tips to help you make the right choice:

– Consider the Material: Different materials require different cutting tools. For example, a tap designed for steel may not work well on aluminum. Make sure you choose a tool that’s appropriate for the material you’re working with.

– Look at the Application: The application will determine what type of cutting tool you need. For example, if you need to create internal threads, you’ll need a die or tap. If you need to create external threads, you’ll need a tap or thread mill.

– Think about Tool Life: Cutting tools wear out over time, which can affect productivity and efficiency. Choose a tool that offers good tool life and performance.

[h2]Conclusion[/h2]

North American Tool is a leading manufacturer of precision threading and grooving solutions. With their extensive product line-up, custom solutions, and innovative products, they have established themselves as a go-to choice for businesses worldwide.

If you’re in search of high-quality cutting tools, North American Tool should be at the top of your list. Their products are designed to meet the highest standards of quality and performance, ensuring that you get the best results every time.

So why wait? Contact North American Tool today and take your business to the next level!

References:

1. https://www.natool.com/

2. https://en.wikipedia.org/wiki/Threading_(manufacturing)