If you’re in the machining industry, you know the importance of precision tools. One key tool that’s essential for achieving accuracy and precision is the taper tool. In this comprehensive guide, we’ll explore everything you need to know about taper tools, including their benefits, types, applications, and how to use them.

What is a Taper Tool?

A taper tool is a cutting tool used in machining operations to create tapered holes or surfaces. It has a conical shape with a gradually increasing or decreasing diameter along its length. This design allows it to cut at different depths or angles within a workpiece. Taper tools come in various sizes and styles, depending on the specific application.

Benefits of Using Taper Tools

Using taper tools offers several advantages over other cutting tools. Here are some benefits of using taper tools:

1. Precision: Taper tools are designed to cut with high precision and accuracy, making them ideal for creating tapered holes or surfaces.

2. Versatility: Taper tools can be used for various applications such as drilling, reaming, countersinking, and more.

3. Efficiency: Taper tools can complete multiple tasks using one tool, saving time and reducing costs.

4. Durability: High-quality taper tools are made from high-speed steel (HSS) or carbide materials, making them durable and long-lasting.

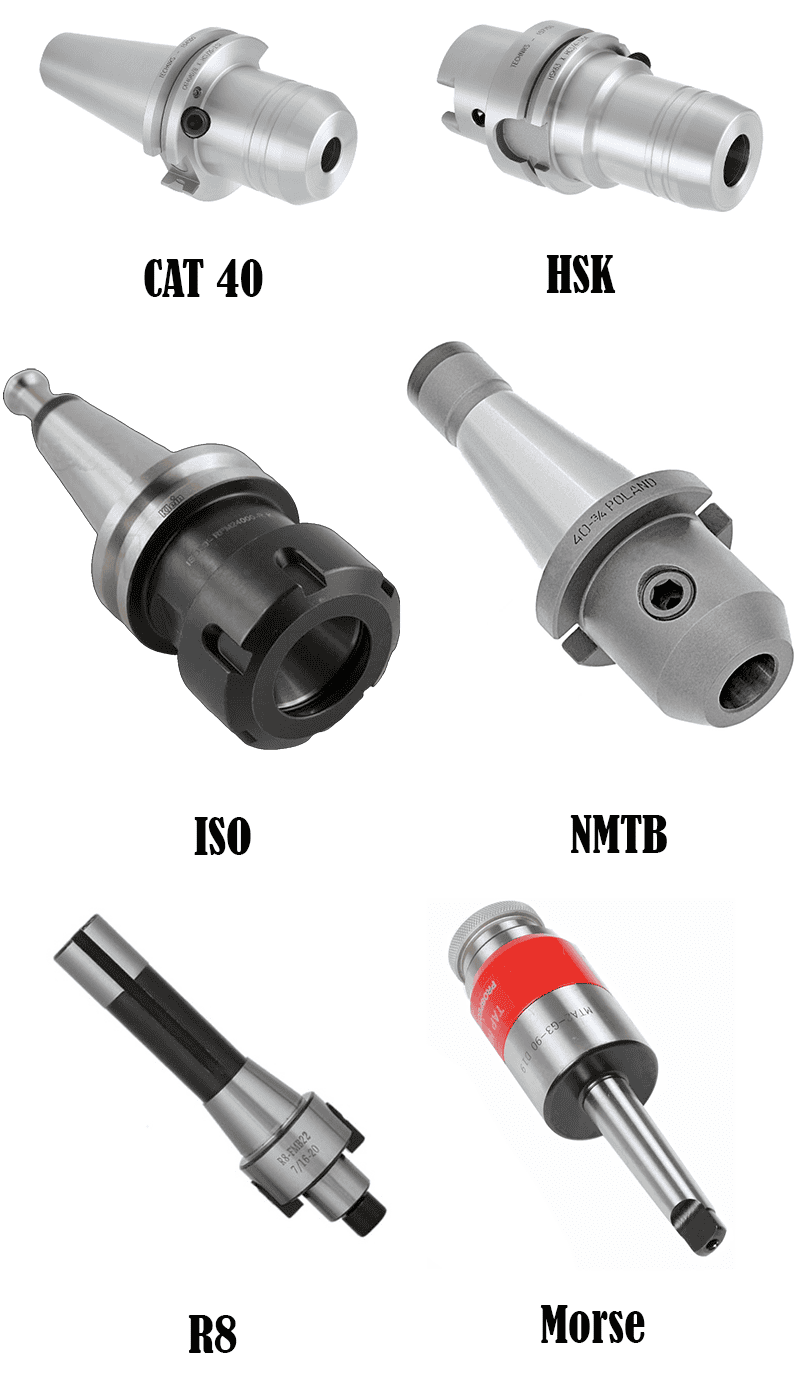

Types of Taper Tools

There are many types of taper tools available on the market today. Each type is designed for specific applications and has unique features that make it suitable for certain tasks. Here are some common types of taper tools:

1. Morse Taper: A Morse taper is a type of drill chuck commonly used in drilling machines. It has a self-locking mechanism that holds the drill bit securely in place.

2. Jacobs Taper: A Jacobs taper is another type of drill chuck used in drilling machines. It has a three-jawed design that holds the drill bit securely.

3. R8 Taper: An R8 taper is commonly used in milling machines. It has a 7/16 inch diameter with a 20-degree taper angle.

4. Bull Nose Taper: A bull nose taper is ideal for creating rounded edges or contours on a workpiece. It has a spherical shape with a gradually increasing or decreasing diameter along its length.

Applications of Taper Tools

Taper tools are versatile and can be used for various applications, including:

1. Drilling: Taper tools are commonly used in drilling operations to create tapered holes in materials such as wood, metal, and plastic.

2. Milling: Taper tools are also used in milling operations to create tapered surfaces or contours on a workpiece.

3. Reaming: Taper tools can be used for reaming operations to enlarge or smooth out an existing hole.

4. Countersinking: Taper tools can also be used for countersinking operations to create chamfers or countersinks on the edge of a workpiece.

How to Use Taper Tools

Using taper tools requires some knowledge and skill. Here are some tips on how to use taper tools effectively:

1. Choose the right tool for the job: Make sure you choose the appropriate taper tool for the specific application you’re working on.

2. Check the tool’s condition: Inspect the taper tool before using it to ensure it’s in good condition and free from damage or wear.

3. Secure the tool properly: Use the appropriate chuck or adapter to secure the taper tool firmly in place before using it.

4. Follow safety guidelines: Always follow safety guidelines when using taper tools, such as wearing protective gear and avoiding loose clothing or jewelry that could get caught in the machine.

Conclusion

In conclusion, taper tools are essential cutting tools for achieving precision and accuracy in machining operations. They offer numerous benefits, including versatility, efficiency, and durability. With the right knowledge and skill, you can use taper tools effectively for various applications. Always choose the appropriate taper tool for the job, inspect it before using it, secure it properly, and follow safety guidelines.

Wiki reference: https://en.wikipedia.org/wiki/Tapered_reamer