Are you someone who frequently uses tools in your work? Have you ever come across the term “tool collet” and wondered what it means? If so, then this article is for you. In this comprehensive guide, we will delve into the world of tool collets and explore their various functions and types.

What is a Tool Collet?

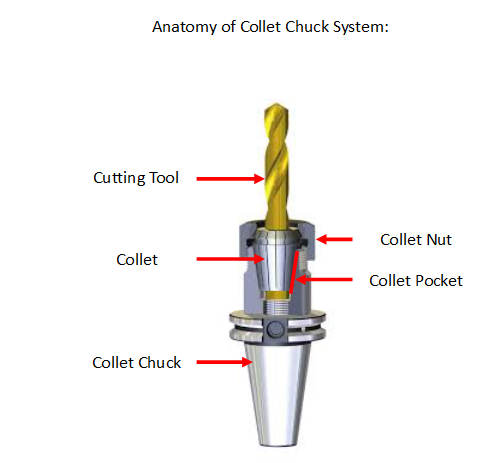

A tool collet is a type of clamping device that is used to secure a cutting tool or other accessory to a machine’s spindle. It is an essential component of many machining processes, as it ensures that the tool remains securely in place during operation. Tool collets are commonly used in milling machines, lathes, and other metalworking equipment.

Types of Tool Collets

There are several different types of tool collets available on the market today. Some of the most common include:

1. ER Collets: This type of tool collet is widely used in milling machines and other metalworking equipment. It has a high clamping force and can hold tools with diameters ranging from 1mm to 20mm.

2. R8 Collets: These are typically used in manual milling machines and have a tapered design that allows for easy insertion and removal of tools.

3. 5C Collets: This type of collet is commonly used in lathes and can hold round or hexagonal parts up to 1-1/16″ in diameter.

4. TG Collets: This collet system is designed for use in turning centers and boring mills. It has a high gripping force and can hold larger tools than many other types of collets.

Functions of Tool Collets

The primary function of a tool collet is to securely hold cutting tools in place during machining operations. This helps to prevent slipping or movement, which can result in poor surface finish, excessive tool wear, or even damage to the workpiece.

In addition to this primary function, tool collets can also help to improve machining accuracy and productivity. By holding tools firmly in place, they allow for more precise cuts and reduce the need for frequent tool changes.

Tips for Choosing a Tool Collet

When selecting a tool collet, there are several factors to consider, including:

1. Size: Make sure that the collet you choose is compatible with your machine’s spindle size and the diameter of your cutting tools.

2. Material: Tool collets are typically made from steel or other metals, but some may be coated with materials like titanium nitride (TiN) to improve their wear resistance.

3. Clamping Force: The clamping force of a collet determines how securely it will hold your cutting tool in place. Look for a collet with a high clamping force if you will be working with heavy-duty materials or performing aggressive machining operations.

4. Ease of Use: Some collets are easier to install and remove than others. Consider whether you need a quick-change system or one that requires more time and effort to set up.

Conclusion

In conclusion, tool collets are an essential component of many machining processes. They provide a secure way to hold cutting tools in place during operation, which helps to improve accuracy and productivity. By understanding the different types of tool collets available and considering factors like size, material, clamping force, and ease of use, you can select the right one for your specific needs.

References:

1. “Tool Holder Basics – Every Machinist Needs to Watch This”, YouTube.com

2. “ER Collets vs R8 Collets”, carbidetoolsource.com

3. “5C Collet System Explained”, practicalmachinist.com

4. “TG Collet Systems”, kennametal.com