When it comes to manufacturing, tools and dies are critical components that help ensure precision and efficiency. These specialized pieces of equipment play a crucial role in the production of everything from automobiles and appliances to electronics and medical devices.

In this comprehensive guide, we’ll cover everything you need to know about tools and dies, including their importance, different types, how they’re made, and much more. So let’s dive in!

What Are Tools and Dies?

Tools and dies are specialized pieces of equipment used in manufacturing processes to shape, cut, or form materials into specific shapes or sizes. They’re typically used in mass production settings where large quantities of identical parts must be produced quickly and efficiently.

Put simply, a tool is any device used for cutting or shaping materials, while a die is a device used for forming materials into specific shapes. Together, these two components work in tandem to create perfectly formed parts with consistent quality.

Why Are Tools and Dies Important?

Tools and dies are essential components of the manufacturing process because they help ensure consistency and accuracy. By using specialized equipment designed specifically for each job, manufacturers can produce high-quality parts at scale.

Without tools and dies, producing high-precision parts would be extremely difficult if not impossible. Additionally, the use of standardized tooling allows manufacturers to reduce costs by streamlining production processes and minimizing waste.

Different Types of Tools and Dies

There are many different types of tools and dies available today, each designed to meet specific needs depending on the material being worked with and the desired end product. Here are some common types:

1. Cutting Tools – Used for cutting through materials like metal or plastic.

2. Forming Tools – Used for shaping materials into specific forms or shapes.

3. Bending Tools – Used for bending sheet metal into various shapes.

4. Punching Tools – Used for punching holes in materials like sheet metal.

5. Extrusion Dies – Used for creating long, continuous shapes like pipes or tubes.

6. Injection Molding Dies – Used for creating plastic parts through injection molding.

7. Progressive Dies – Used for punching multiple holes in a single stroke.

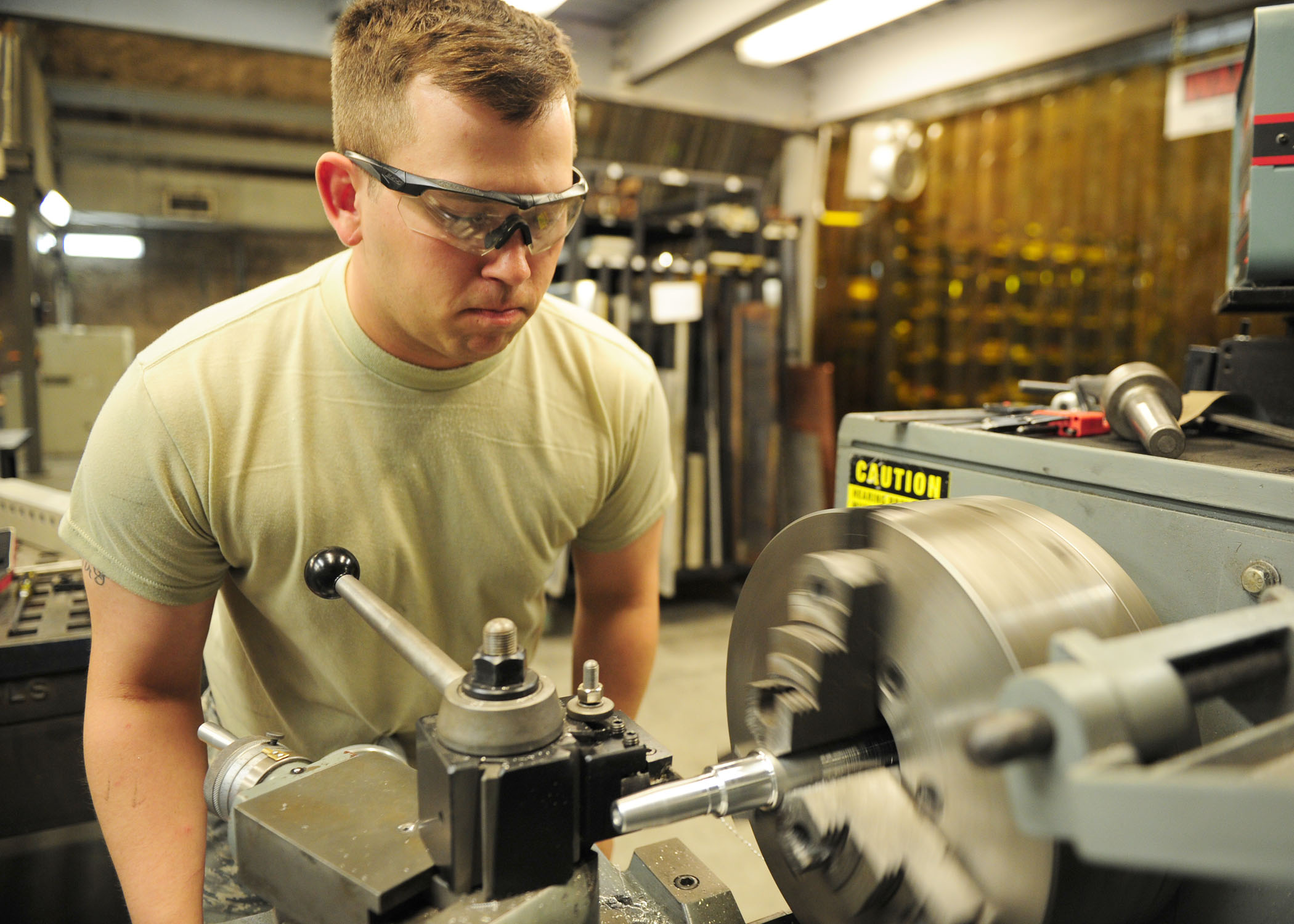

How Are Tools and Dies Made?

Tools and dies are typically made from high-strength materials like steel or carbide, which are able to withstand the high pressures and stresses involved in the manufacturing process.

The process of making tools and dies typically involves several steps, including:

1. Design – The first step is to design the tool or die using specialized software that can account for factors like material thickness, desired tolerances, and part complexity.

2. Machining – Once the design is complete, the tool or die is machined using a variety of cutting tools to create the desired shape and form.

3. Heat Treatment – After machining, the tool or die is subjected to heat treatment to improve its strength and durability.

4. Finishing – Finally, the tool or die is finished with coatings or other surface treatments to protect it from wear and corrosion.

Tips for Choosing the Right Tools and Dies

Choosing the right tools and dies for a specific manufacturing job can be challenging. Here are some tips to help you make the right choice:

1. Consider Material Properties – Different materials have different properties that can affect how they respond to cutting or forming processes. Make sure you choose tools and dies that are designed specifically for your material type.

2. Look for Precision – When producing high-quality parts, precision is key. Choose tools and dies that are designed to provide accurate cuts or forms every time.

3. Consider Cost – While quality should always be a top consideration, cost is also an important factor when choosing tools and dies. Look for options that offer a balance between quality and affordability.

Conclusion

In conclusion, tools and dies play an essential role in modern manufacturing processes. By using specialized equipment designed specifically for each job, manufacturers can produce high-quality parts at scale while minimizing waste and streamlining production processes.

Whether you’re looking to cut, form, bend, punch, or extrude materials, there’s a tool or die out there that’s perfect for the job. By following these tips and considering your specific needs, you can choose the right tools and dies to help you achieve your manufacturing goals.

References:

1. https://en.wikipedia.org/wiki/Tool_and_die_making